We Have Heard You

We have been listening, learning, and reflecting. We have made changes based on your feedback and we will continue to listen and respond to your concerns and questions.

We have updated this website to include details about the facility and the re-design, including its impacts and benefits. We encourage you to reach out if you have a question or concerns we haven't addressed.

Community members are rightfully concerned how the proposed on-farm biodigester facility may contribute to ongoing, existing odour issues in the area. We want to assure you odour conditions will improve, not worsen.

The Rimrock Cattle Company Ltd. feedlot will continue to emit odours as part of feedlot operations whether the proposed biodigester is built or not. Biodigestion is a proven technology that is currently the most advanced and effective option to reduce feedlot odours.

How? The biodigester facility will capture odour-causing greenhouse gases from feedlot manure and, through a fully closed system, convert them to a usable energy resource called renewable natural gas (RNG). Today, those greenhouse gases are currently being released to the atmosphere. It will also help reduce feedlot operational odours by doubling the rate of livestock pen cleanouts and reducing the need for seasonal storage of raw manure at the feedlot (because feedlot manure will be used as feedstock instead).

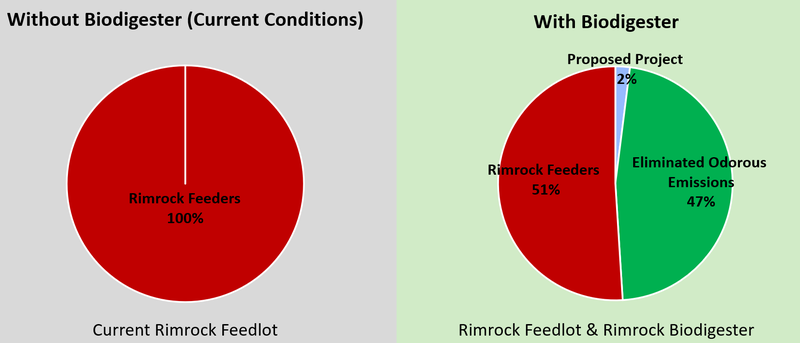

Based on air quality modelling completed by a qualified third party in July 2023, the operation of the proposed biodigester facility is predicted to result in an approximate 47% net reduction in feedlot odour. This approximate net decrease of 47% considers:

- 49% reduction in feedlot odours due to pen cleanout frequencies and manure stockpiling reductions.

- 2% addition and inclusion of potential odour sources introduced by the biodigester facility (e.g., solid digestate staging, manure staging, and liquid digestate pond).

We agree that community members should not be subjected to additional odours as a result of the proposed biodigester facility, and we are committed to doing our part by designing the facility to mitigate potential odours and implementing best odour management practices at the facility.

From the beginning, the proposed biodigester facility design includes key odour abatement features, such as:

- Anaerobic digester tanks that operate as a fully closed system.

- Biogas upgrading where activated carbon filters and ammonia scrubbing vessels will trap volatile organic compounds (VOCs), ammonia (NH3) and hydrogen sulfide (H2S), to produce pipeline quality RNG which will be injected into the local ATCO Gas distribution system.

- Screw presses that will separate digestate into solid and liquid fractions for odour mitigation in both the staged solid and liquid digestate.

Recent design changes have also been made to further mitigate potential odours, including new odour abatement technologies such as:

- Enclosed feedstock receiving area, including building and tanks, organic food resource tanks, and digestate separation building and tanks are all connected to the odour abatement system, removing approximately 95% of odorous emissions from those sources.

- Mechanical aeration in the first cell of the liquid digestate pond will remove approximately 95% of odorous emissions from the entire pond through oxidation.

See the Odour Abatement Technologies section of the Facility Information page for more details.

Odour reduction strategies will also be implemented throughout the facility lifecycle through a continuously improving odour management control plan which will include:

- Administrative controls like operator training and awareness, and the establishment of rigorous maintenance, inspection, and cleaning schedules.

- Odour management procedures for manure and organic food resources transportation, receiving and processing.

- Odour prevention and control measures that will be implemented during both standard and non-standard operating conditions (start-up, shut-down, maintenance and/or upset operating conditions).

- Routine monitoring of the performance of the anaerobic digesters and facility odour containment and control equipment as part of the facility inspection and maintenance program. For example, gas detectors will be used as an operational tool to adjust the feedstock schedule if undesired gasses are being produced.

Any conditions stipulated in the EPEA approval, if granted, related to air emissions limits, monitoring and reporting, along with any odour management requirements for the facility will be strictly adhered to. The EPEA approval and conditions will be publicly available.

Regional Air Quality and Odour Monitoring

Regionally, in 2022, the Calgary Region Airshed Zone (CRAZ) and Town of High River announced a partnership in concert with Alberta Environment and Protected Areas to bring air quality monitoring to High River with one objective being the establishment of a baseline Air Quality Index for the area. The Natural Resources Conservation Board (NRCB) has also installed a CTair unit at the same location as the CRAZ sensor to measure additional air quality parameters specific to feedlots. The CTair unit will provide the NRCB with another tool to help monitor and address odours related to the Rimrock Cattle Company Ltd. feedlot west of High River.

Recognizing the proposed facility is in an area of high existing odour sources such as other feedlots, a meat processing facility, a wastewater treatment facility, and a landfill, Rimrock is open to cooperating and supporting a regional monitoring program through the Province, County, or other organization.

Residents in the area have expressed concerns about the biodigester and the possibility that it could lead to an expansion of the feedlot’s capacity. We want to assure you, the biodigester will not, and cannot, have any impact on the size of the feedlot.

The feedlot will continue to operate as part of the community whether the biodigester facility is constructed or not.

The feedlot is regulated by the Natural Resources Conservation Board (NRCB) under the Agricultural Operation Practices Act. Any AEPA decision regarding the proposed Project is independent of the NRCB permit. The NRCB permit regulating the feedlot will not be affected by AEPA's decision regarding Rimrock's application for a biodigester facility.

The operation of the biodigester will not impact the existing feedlot permit or enable a feedlot expansion in any way.

The existing feedlot has been active since the 1980’s and operated by Rimrock Cattle Company Ltd. since 2019. The NRCB will not allow for feedlot expansion beyond the permitted capacity of 35,000 beef finishers.

The biodigester would create a significant change in manure handling and storage practices at the feedlot resulting in a material decrease in feedlot odours.

Manure handling practices will change from long term stockpiling, to transporting manure to the adjacent on-farm biodigester facility for processing. Manure will be transported using a private internal connecting road from the feedlot to the biodigester facility, reducing public road traffic.

Community members have expressed concern about the liquid digestate pond. Although liquid digestate is materially less odorous compared to raw manure, we have carefully considered your concerns and have redesigned the pond to have mechanical aeration that will approximately 95% of odorous emissions.

In response to community feedback about the digestate pond size and potential odour, Rimrock has conducted multiple detailed assessments and has further identified opportunities to revise the pond design.

As part of the facility redesign we have proposed the following high-value opportunities to further reduce the risk of odour emissions from the pond:

- Mechanical separation of digestate into solid and liquid fractions using screw presses provides an odour mitigation for the liquid digestate pond by removing a large portion of the remaining organic compounds that would otherwise be discharged into the liquid digestate pond following the digestion process.

- Reuse of liquid digestate in the facility process upstream of the liquid digestate pond. This will decrease freshwater requirements and the size of the liquid digestate pond by approximately half. Through liquid digestate reuse that decreases freshwater requirements and the size of the liquid digestate pond.

- Design of a two-celled liquid digestate pond with mechanical aeration within the first cell that will remove approximately 95% of odorous emissions through oxidation.

Additionally, moving the digestate separation building to the northeast side of the facility has allowed for heat recovery from the liquid digestate as it is transported from the screw presses to the liquid digestate pond. This will further reduce the facility’s environmental footprint by repurposing thermal energy reducing the temperature of the liquid digestate entering the pond.

We have also heard your concerns on how the pond will be operated to mitigate potential wildlife impacts.

Liquid digestate is a benign by-product of the anaerobic digestion process and the digestate pond has been designed as a semi-active system and with a reduced surface area, to reduce attraction of wildlife. That being said, we continue to review the potential need and appropriateness of deterrents, as part of detailed design. We are also committed to actively monitoring the digestate pond during operations to determine whether additional mitigations are required to reduce potential wildlife interactions with the pond.

More information about the liquid digestate pond can be found on the Facility Information page.

We know there are unanswered questions and concerns about the organic food resources that the biodigester will be processing along with feedlot manure.

We can confirm that unprocessed organic food resources will not be used or stored onsite.

Organics will be pre-processed offsite (i.e., de-packaging of any styrofoams, plastics) and delivered to the facility in fully enclosed trucks. Upon arrival, organic food resources will be transferred directly into fully enclosed organic food resource tanks, where they will be mixed with additional water and heated, before being sent through underground piping directly to the enclosed anaerobic digester tanks. Deliveries will be scheduled based on operational needs, to avoid any onsite storage needs.

All organic food resources accepted at the facility will be in accordance with the June 2023 Memorandum of Understanding (MOU) among Alberta Agriculture and Irrigation (AGI), Alberta Environment and Protected Areas (EPA), and the Natural Resources Conservation Board (NRCB) regarding the storage and application of digestate on agricultural land.

Potential organic food resources that may be used at the facility include fats, oils and greases, food processing residues, kitchen and market residues, horticultural residues, garden residues, energy crops, damaged/rejected crops, and crop residues. The facility will not have the infrastructure, or be permitted to, process specified risk materials (SRM) or carcasses.

We hear that you care about the impact this facility will have on the environment. We care too – that is why we are considering environmental impact, from benefits to potential effects, every step of the way.

This biodigester facility will turn waste into energy and will reduce greenhouse gas emissions. We consider this a huge win for the environment and has a high potential to improve odours for rural communities in close proximity to agricultural operations.

The biodigester facility will capture greenhouse gases from livestock manure and organic food resources and convert them to a usable energy resource called renewable natural gas (RNG). The biodigester facility will also create a natural fertilizer (digestate) to offset synthetic fertilizer use. This is aligned with federal initiatives and will support the local agrifood industry by reducing the reliance on non-local synthetic fertilizers.

The most appropriate sourcing and efficient use of water for the biodigester facility was determined with environmental consideration, and adherence to licensing and regulatory guidelines.

All water will be sourced from the Highwood River, not groundwater. Rimrock obtained a water licence transfer from AEPA for the Highwood River under the Water Act. It is important to understand that this is not a new licence, but a transfer of an existing licence, and that 10% of the licence volume has not been transferred to Rimrock. This holdback means the licence transfer decreases the allowable water withdrawals from the river.

Some ways that we are reducing water usage and protecting water resources:

- Water withdrawal volumes will be measured and tracked to ensure that all water used is under the licenced limit.

- Following the extensive assessment of liquid digestate reuse, the facility has the potential to reuse liquid digestate upstream of the digestate pond in the facility process. This will decrease freshwater requirements and the size of the liquid digestate pond.

- To prevent any impact to existing groundwater conditions Rimrock is implementing groundwater protection and monitoring (including secondary containment and a groundwater monitoring program), in accordance with Alberta Environment and Protected Areas secondary containment guidelines.

- Any conditions stipulated in the EPEA approval, if granted, related to groundwater quality monitoring and reporting for the facility will be strictly adhered to. The EPEA approval and conditions will be publicly available.

- Rimrock will continue to assess potential opportunities to decrease freshwater needs for the facility throughout the design process and will keep you informed along the way.

Air emissions from the facility are designed to comply with ground-level ambient air quality.

An updated Air Quality Assessment using air dispersion modelling conducted in accordance with the Alberta Air Quality Model Guideline has been completed for the proposed facility. The maximum off-site ground-level concentrations for relevant contaminants of concern are predicted to comply with – in fact be well below – the Alberta Ambient Quality Objectives (AAAQO). Any conditions stipulated in the EPEA approval, if granted, related to air emissions limits and monitoring and reporting for the facility will be strictly adhered to. The EPEA approval and conditions will be publicly available.

More information about environmental protection can be found on the FAQs page.

We know there are questions about the economic impact this facility will have on the community and on you personally. We are confident this facility will contribute to economic growth in the area and will have a positive effect on property values for the local community.

This facility will generate valuable tax dollars for the County. We predict the construction activities will create over 200 positions throughout construction of the facility, as well as bring additional opportunities for local contractors, suppliers, restaurants, and service providers. We also expect the odour reduction will have a positive effect on regional property values.