Rimrock Biodigester Facility – Transforming Greenhouse Gases into Renewable Energy

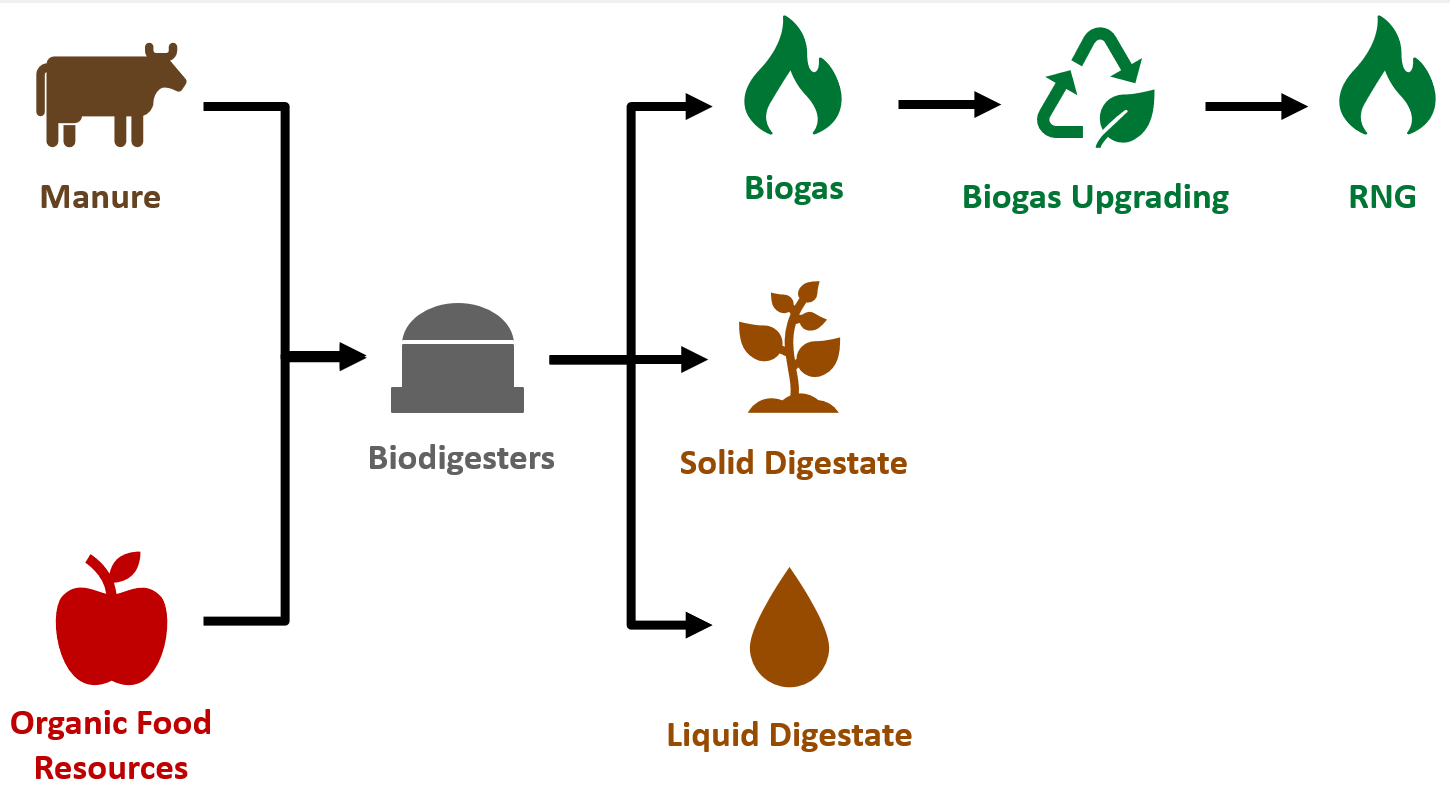

Rimrock Renewables LP is proposing to construct an on-farm biodigester facility to capture greenhouse gases from livestock manure and organic food resources and convert them to a usable energy resource called renewable natural gas (RNG). Today, those greenhouse gases (which are also odour causing), are being released to the atmosphere. The primary objective of the Rimrock Biodigester Facility is to capture as much of those gases as possible.

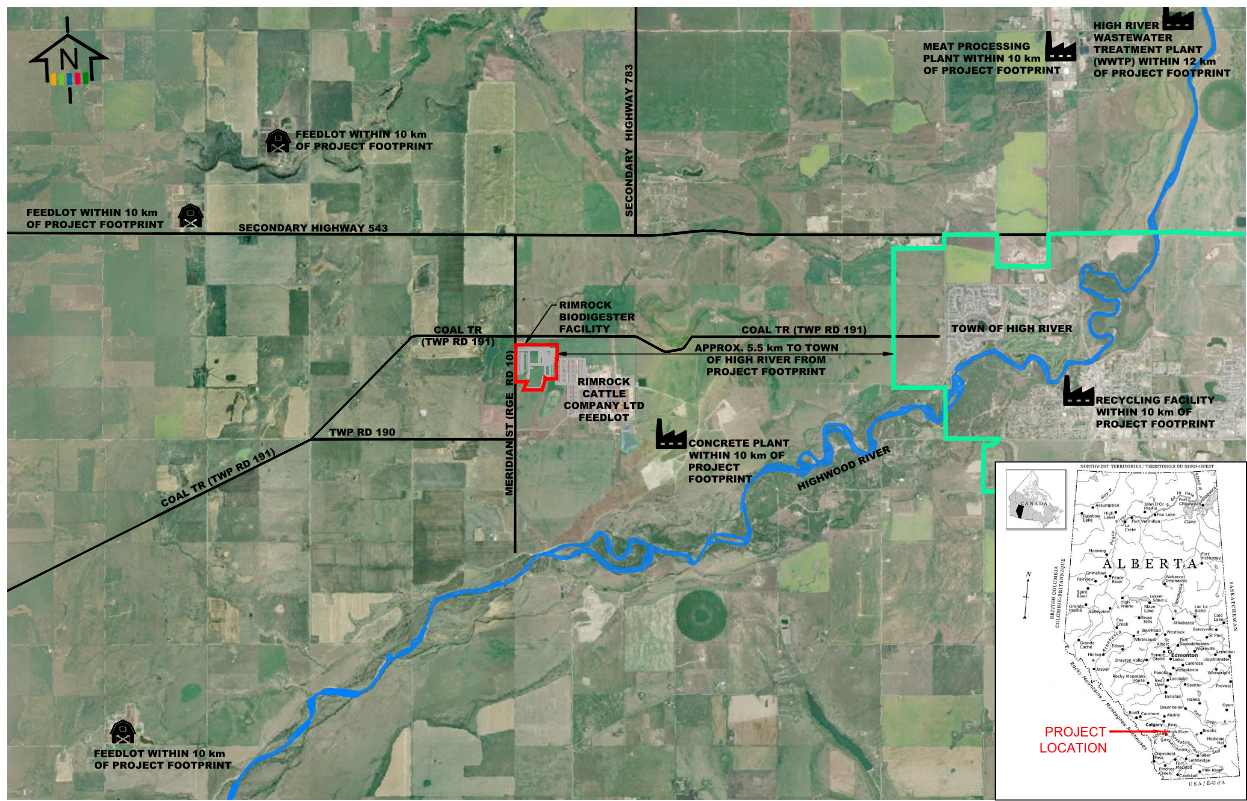

Proposed Facility Location

The proposed Rimrock Biodigester Facility will be an “on-farm” facility, co-located with the Rimrock Cattle Company Ltd. feedlot. Located within Foothills County, approximately 5.5 km west of the Town of High River, the proposed Rimrock Biodigester Facility will occupy approximately 40 ha southeast of the intersection of Coal Trail (Township Road 191) and Meridian Street (Range Road 10).

The Rimrock Cattle Company Ltd. feedlot will be the primary source of feedstock (livestock manure) for the biodigester facility, meaning the manure that is currently stored on the feedlot will be transferred approximately 200 m – 300 m to the biodigester facility where it will be anaerobically digested to capture odorous gases and produce RNG.

Like most biodigester facilities in Canada, and globally, the facility is located adjacent to the primary source of feedstock. Locating biodigester facilities immediately adjacent to the primary source of feedstock enhances environmental benefits (e.g., net decrease in greenhouse gas emissions) through reduced transportation requirements and hauling distances.

Rimrock Biodigester Facility Description

Feedstock for the proposed biodigester facility will primarily consist of livestock manure from Rimrock Cattle Company Ltd. feedlot, along with organic food resources. Raw un-hydrated manure will be transported to the facility via a private internal road from the adjacent feedlot. Organic food resources will be sourced as close as possible to the proposed biodigester facility, depending on availability, quality, and specifications of the material.

The feedstock will undergo anaerobic biodigestion in fully contained anaerobic digesters where micro-organisms (bacteria) will break down the organic material within the feedstock, in the absence of oxygen, producing biogas and digestate.

The biogas will be upgraded onsite at the biodigester facility to produce pipeline quality RNG which will be injected into a low-pressure ATCO Gas distribution pipeline to serve the local community.

Digestate, a beneficial by-product of the biodigestion process, will be used for application to lands as a less odorous, biologically stabilized fertilizer alternative to raw manure, which is currently being land spread in the region.

Click on the interactive image below to learn more about how the biodigester facility will operate:

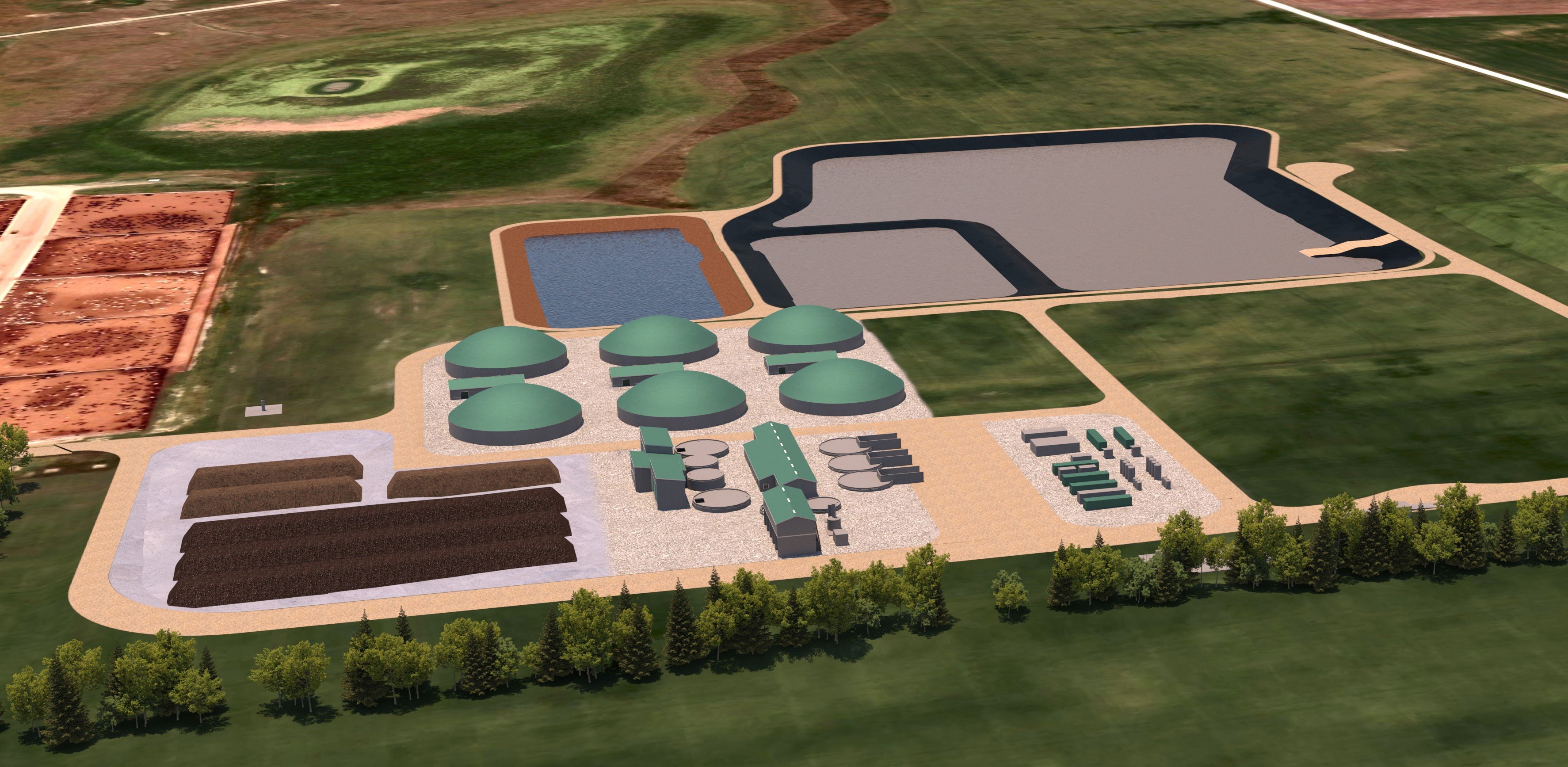

Internal Gravel Road

The Rimrock Cattle Company Ltd. feedlot and the proposed Rimrock Biodigester Facility will be connected by a private internal gravel road to transport manure from the feedlot to the feedstock receiving area. This will avoid the use of public roads for manure transportation.

Feedstock Receiving Area

As part of recent design updates, the previously proposed manure blend building has been replaced with a feedstock receiving system. Raw (un-hydrated) manure will be trucked in from the adjacent feedlot and transferred into one of two enclosed and recessed feedstock receiving hoppers. From the hoppers, raw manure will be augured into the enclosed manure blend tanks for partial hydration and then in the digester feed tanks where it will be fully hydrated, agitated and pumped to the anaerobic digester tanks. The enclosed feedstock receiving hoppers, feedstock building, manure blend tanks, and digester feed tanks will be tied directly into an odour abatement system.

See the Odour Abatement Technologies section below for more details about this update.

Organic Food Resource Tanks

Organic food resources will be trucked to the facility via external roads in contained delivery vehicles to mitigate the potential for odour releases. Upon arrival, organics will be transferred into covered organic food resources tanks for processing before being fed via underground piping into the digester tanks. The headspace of the organic food resource tanks will be directly connected to an odour abatement system.

See the Facility Operations section of the FAQ page to learn more about organic food resources feedstock.

Freshwater Reservoir Pond

The water source for the facility will be the Highwood River, granted under an approved water license transfer. Groundwater will not be used. A clay-lined freshwater reservoir will be used to temporarily hold water from the Highwood River prior to being used to hydrate and blend with manure and organic food resources. No process water or runoff will be stored in the freshwater reservoir.

See the Water section of the FAQ page to learn more about water use.

Anaerobic Digester Tanks

Six (6) anerobic digestion tanks are proposed to receive and process manure and organic food resources feedstock. During anaerobic digestion, micro-organisms will break down the organic material within the combined feedstock, in the absence of oxygen, producing two products: biogas and digestate. The anaerobic digestion process will occur at a temperature of approximately 38oc over approximately 30-days. These fully enclosed tanks will be equipped with double-layer membranes to contain the biogas at low pressure as well as any odours that may result from the process.

See the Anaerobic Digestion section of the FAQ page to learn more.

Biogas Upgrading & Cogeneration

Biogas taken from the anaerobic digesters needs to be upgraded before being utilized as RNG. During biogas upgrading, activated carbon filters and ammonia scrubbing vessels will trap volatile organic compounds (VOCs), ammonia (NH3) and hydrogen sulfide (H2S), to produce pipeline quality RNG which will be injected into the local ATCO Gas distribution system.

See the RNG section of the FAQ page to learn more.

Two micro-generation sized cogeneration units, with a combined maximum output of approximately 2 megawatts (MW), will be installed onsite to produce electricity and heat needed to support facility operations.

Digestate Separation Building

Digestate material will be taken from the anaerobic digesters through underground piping to the digestate separation building. Screw presses will be used to separate the digestate into solid and liquid fractions which will serve to mitigate odours in both the staged solid digestate and the liquid digestate pond. Co-locating the digestate separation building, digestate nurse tank, and liquid digestate tank will allow this system to be vented to the same odour abatement system.

See the Anaerobic Digestion section of the FAQ page to learn more about digestate.

Odour Abatement System

As part of recent design updates, all tanks involved in feedstock receiving and digestate separation (two manure blend tanks, two digester feed tanks, three organics reception tanks, one digestate nurse tank and one liquid digestate tank) will be enclosed, under negative pressure, and tied into an odour abatement system via sealed ducting.

The odour abatement system will also treat air from all buildings that have the potential to produce odours: the feedstock hopper building, feedstock receiving hoppers, feedstock pumphouse building, and digestate separation building.

See the Odour Abatement Technologies section below for more details about this update.

Staging Area

Solid digestate will be temporarily stored on-site before being spread on Foothills County lands twice a year (spring and fall). As part of recent design updates, the capacity of the solid digestate staging area has been greatly reduced to 22% of the annual solid digestate production, with the remaining 78% transferred to the adjacent feedlot to be used as cattle bedding or spread on local lands as a fertilizer. The solid digestate staging area has also been relocated to the northeast quadrant of the facility so that it is immediately adjacent to the feedlot.

Rimrock is proposing to stage a small volume of manure onsite at the facility, limited to 6% of the total annual manure feedstock, as a contingency, in the event all manure can't be loaded immediately into the hoppers. Staging manure here, rather than 200-300 m away at the feedlot will reduce handling which maximizes the environmental benefits and reduces odorous emissions.

Aerated Liquid Digestate Pond

Liquid digestate will be collected in an onsite digestate pond with an impermeable high-density polyethylene (HDPE) liner. As part of recent design updates, the liquid digestate pond design has been optimized to a two-cell pond configuration with mechanical aeration which has allowed the pond to be reduced by half the size of the original design. Mechanical aeration in the first cell will remove approximately 95% of odorous emissions through oxidation. The second cell will be used for storage of the fully stabilized liquid digestate after aeration occurs. Liquid digestate will be pumped from the pond and applied to agricultural lands as an alternative to synthetic fertilizers. As a result, the digestate pond will be drained every 6 months and take another 6 months to fill up again keeping the active depth of liquid in the pond to a minimum to avoid aerobic conditions and further reduce the risk of odours.

See the Odour Abatement Technologies section below for more details about this update.

Odour Abatement Technologies

Based on feedback from local landowners and residents and Alberta Environment and Protected Areas, we are proposing notable improvements to the overall Project design, including the implementation of additional odour abatement technologies.

In selecting the optimum design refinements and odour mitigation strategies, our team has spent the last several months reviewing best available technologies for odour abatement, consulting with research and industry experts, and working intensively with engineering, environmental and regulatory consultants.

Enclosed and Efficient System

As part of recent design updates, the facility layout has been rearranged to co-locate the digestate separation and staging processes alongside the feedstock receiving operations. This has been done so that all tanks involved in feedstock receiving and digestate separation (two manure blend tanks, two digester feed tanks, three organics reception tanks, one digestate nurse tank and one liquid digestate tank) will be enclosed, under negative pressure, and tied into an odour abatement system via sealed ducting. The odour abatement system will also treat air from the feedstock hopper building, feedstock receiving hoppers, feedstock pumphouse building, and digestate separation building.

We have also replaced the previously proposed manure blend building with a feedstock receiving system that is designed so that raw manure receiving hoppers will be placed in an enclosed building and connected to the same odour abatement system. To minimize handling, trucks transporting raw manure from the feedlot will unload the feedstock directly into enclosed, odour abated, receiving hoppers. Also, manure hydration will only occur in enclosed tanks that are tied to an odour abatement system.

Odour Abatement System

A 2-stage odour abatement system has been selected that will remove approximately 95% of odorous emissions from all tanks involved in feedstock receiving and digestate separation, as well as the feedstock hopper building, feedstock receiving hoppers, feedstock pumphouse building, and digestate separation building.

- Stage 1 – Wet Chemical Scrubber: Wet chemical scrubbers operate by bringing a scrubbing liquid into contact with an odorous gas stream. The liquid absorbs (reacts with) the targeted odorous compounds, effectively removing them from the process air. Wet chemical scrubbers, including the one proposed as part of the facility odour abatement system, are well demonstrated to operate with very high removal efficiencies (exceeding 95%).

- Stage 2 – Activated Carbon Filter: Activated carbon filters, also known as carbon adsorption systems, will treat all process areas that can be enclosed and vented to produce a controlled air stream. Activated carbon filters utilize a sealed vessel filled with porous bulk carbon material, with a large surface area to adsorb odorous compounds. The odorous air passes through the carbon beds, and the compounds are physically adsorbed onto the carbon's surface. Activated carbon filters are very effective in removing a wide range of odorous compounds with a well demonstrated removal efficiency of approximately 95%.

Optimized Liquid Digestate Pond

The liquid digestate pond has undergone a redesign to optimize its performance and reduce the risk of potential odours. The new two-celled configuration will consist of a polishing cell complete with mechanical aeration, and a storage cell. The polishing cell and mechanical aeration system were appropriately sized to satisfy demand from oxidation of any biodegradable organic material, and from oxidation of dissolved sulfides, and ensures aerobic conditions to prevent further generation of volatile organic compounds (VOCs) and hydrogen sulfide (H2S). The material leaving the polishing cell will be fully stabilized, so no anaerobic activity is expected in the storage cell. Mechanical aeration is a proven technology and as sized anticipates removing approximately 95% of VOCs and H2S in the liquid digestate through oxidation. Additionally, the active depth of both the polishing and storage cells were optimized to further reduce the risk of odour generation.

What are the Proposed Facility’s Environmental Benefits?

This proposed biodigester facility will turn waste into energy and will reduce greenhouse gas emissions. We consider this a huge win for the environment and it has a high potential to improve odours for rural communities in close proximity to agricultural operations.

The proposed biodigester facility will:

- Reduce greenhouse gases by capturing odour causing gases and convert them to a usable energy resource called renewable natural gas (RNG). Today, those greenhouse gases (which are also odour causing), are being released to the atmosphere.

- Reduce storage time for livestock manure at the Rimrock Cattle Company Ltd. feedlot, reduce odours from land application and support improved management of pens and land application.

- Produce digestate, a beneficial by-product of the biodigestion process, will be used for application to lands as a less odorous, biologically stabilized, organic fertilizer alternative to raw manure, which is currently being land spread in the region.

- Provide a sustainable waste management strategy in conjunction with the agricultural livestock and energy sectors.

- Produce enough renewable natural gas to heat ~6,000 homes per year (450,000 Gigajoules of RNG per year) in Foothills County. RNG produced will be used in place of natural gas, reducing reliance on fossil fuels.